compressor seal testing|nitrogen gas seal performance : white label The dry-gas seal (DGS) is a critical integrity component of the centrifugal or screw compressor, providing shaft sealing and pre-venting uncontrolled escape of process gas from the . See more 12/03/2021. IMAGENS FORTES! Facção criminosa ‘Comando Vermelho’ executa mulher a tiros após confessar crime: 'meus amigos do CV mandaram eu parar, me deram um .

{plog:ftitle_list}

WEB4 de mar. de 2017 · Vicuna Mackenna 27° 19°. Villa Carlos Paz 28° 17°. Villa María 28° 20°. Tiempo en Tanti Nuevo - Pronóstico del tiempo a 14 días. Los datos sobre el Tiempo, temperatura, velocidad del viento, la humedad, la cota de nieve, presión, etc.

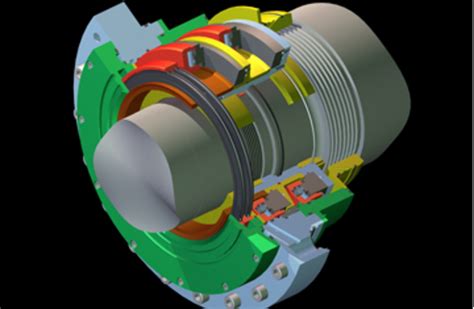

The dry-gas seal (DGS) is a critical integrity component of the centrifugal or screw compressor, providing shaft sealing and pre-venting uncontrolled escape of process gas from the . See moreFor use as seal gas, the gas must be At a higher pressure than the operating pressure of the primary seal (typically recommended by the . See more

For process engineers that work in the early phases of a design project (e.g., front-end engineering design), when minimal equip-ment data are available, the compressor DGS interfaces are often deferred to a later stage, awaiting manufacturer’s data, . See more20K RPM Dry Gas Seal Tester. This system is designed to evaluate dry gas compressor seals and it automates the 4-6 hour testing that is performed on each set of seals. Vidac high .Alberta Energy Regulator (AER) Directive 060 requires operators to periodically measure venting from compressors which includes piston-rod-packing, the distance-piece and the crankcase. This summary provides an interpretation of . The seal panel, the seal piping arrangements, and the seal vent system details are critical for reliability, performance, safety, and operation of .

Compressor Dry Gas Seal Testing We have the capability to test compressor dry gas seals in all sizes. Seals are dynamically tested to API requirements. Test reports and a full certification pack is supplied with each seal. AESSEAL® welcome customers to witness the testing of their seals at the state of the art test facility. The Currently, control seals installed at an NREL test compressor have run for 120 hours as of September 2019. The test compressor is operated 8 hours per day, and further automation is being explored to accelerate the testing. These seals will be run until they experience a failure, after which seals with a PTFE coating will In this HVAC Training Article, I discuss how to perform electrical troubleshooting on an HVAC/R compressor to determine if it is bad. Too many times, compressors are condemned without taking the proper measurements .

Novel Foil Seals Designed and Developed to Meet Hydrogen Compressor Requirements • Seal Design Analysis Methodology Developed • Seal Performance Testing Completed • Compliant Foil Seal Operation Demonstrated – Non-Contact, Close Clearance Film Riding Seal Operation – Testing at . Δ. Pressure above 200 psig Successfully Completed – Designers look at various process parameters when selecting a dry gas seal for a centrifugal compressor. Operating speed is particularly pertinent for hydrogen service. . We’re constantly innovating materials and testing new sealing and support system technologies, including those that address hydrogen gas compression. In doing so, we equip .A sealing gas is injected into the seal, providing the working fluid for the running gap and the seal between the atmosphere or flare system and the compressor internal process gas. Primary Dry Gas Seal: Preventing leakage of working gas from a machine’s inner side. Secondary Dry Gas Seal: Backing up the first dry gas seal.Compressor seal vent gas flow rate testing and recording. Cookies on CSA Group. We use cookies to enhance your browsing experience, serve personalized content, and analyze our traffic. Cookies are small files of information stored on your device that help us remember your preferences and improve your experience. By clicking ‘Accept All .

Aggressive Testing Protocol for H. 2 . Compressor Gaskets (NREL & GVD) Working with NREL to quantify improved lifetime of seals in HydroPac compressors Establishedtest conditions for an aggressive thermal cycling with a plan for automated operation to accelerate results. ~50. hours of run time logged on control seals to date. Testing delayed due to The seal gas booster is used to guarantee supply of conditioned gas flow and pressure differential to the dry gas seals at compressor standstill. As the title of API 692 suggests, its purpose is to stipulate the minimum requirements for dry gas sealing systems, or the conditions you need to run your centrifugal compressors reliably.

compressor test. Tests that need to be carried out with the engine running must only be performed in spaces equipped with an exhaust extraction system, or outdoors. . Testing the tightness of the compressor cylinder head: – Seal a coolant port (e.g. port 9.1). – Connect a compressed air adapter to the second coolant port.Aggressive Testing Protocol for H. 2 . Compressor Gaskets (NREL & GVD) Working with NREL to quantify improved lifetime of seals in HydroPac compressors Establishedtest conditions for an aggressive thermal cycling with a plan for automated operation to accelerate results. ~50. hours of run time logged on control seals to date. Testing delayed due toCompressor surge is a cyclic event and this results in high strain on compressor bearings, seals, and the impeller. The resulting severe vibration can lead to damage to the motor compressor coupling and the baseplate. . deg.C depending on the manufacturer and believes that this is due to a variety of operating conditions between string test .Title: Compressor seal vent gas flow rate testing and recording To register for e-mail notification about any updates to this publication • go to store.csagroup.org • click on Product Updates The List ID that you will need to register for updates to this publication is 2428272.

Abstract. In centrifugal compressors, the shaft seal clearance is critical to equipment efficiency and performance. Applications employing very small seal clearances must rely on abradable materials in the stator (housing) to prevent damage to rotating components in the case of rubs. An interaction (or rub) between the rotating seal geometry and stationary .Seal qualification test (I.3.5) Category 1 seal Required – Category 2 seal Applicable for same seal design Required – Category 3 seal Applicable for same seal design Required Data requirements (Annex J) (7.1.2.9) Proposal Minimal Rigorous Contract Performance curve of internal circulation device If specified Required * API paragraphs in .This system is designed to evaluate dry gas compressor seals and it automates the 4-6 hour testing that is performed on each set of seals. Vidac high pressure testers include a full complement of support equipment. We have integrated the actual high pressure controls, valving and instrumentation into a control system that provides tightly .

systech illinois water vapor permeability tester service

and finally, dynamic testing of the final full-scale design will be completed to demonstrate that performance capabilities meet the specified needs of a hydrogen transportation and delivery compressor. Approach Additional testing will be performed using the seal design and hardware developed under Phase I to

secondary gas seal performance

The rotating seat of a DGS compressor seal is grooved to ensure the gas separation film forms and stabilizes during dynamic operation, including compressor start-ups . prior to the dynamic test. The master tests for each seal also simulate particular operational issues of LNG compressors that represent major challenges for dry gas seals, like:

The seal gas supply pressure MUST be a higher pressure than the compressor seals will ever encounter. The “clean, dry and cool” specification can be accomplished by installing filters, driers and coolers in the seal gas supply line. The separation gas is usually an inert gas such as nitrogen and should be dry and cool. Pressure testing is a critical aspect of pipeline testing before first use as it determines readiness for full operational use. During pressure testing activities, various parameters are analyzed including the following: Maximum permissible pipeline capacity; Leak checking; Joint fitting stability; Pressure ratings; Component reliability About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

water vapor permeability test cup service

Wall Seal 2ndSection 1stSection Gas Flow Path Typical High Pressure Centrifugal Compressor Sample 10-Stage Compressor Model Shaft1 79 75 70 45 50 55 60 65 40 15 20 25 30 35 5 10 haft1 1 Reference: Moore, J.J., Soulas, T.S., 2003, “Damper Seal Comparison in a High-Pressure Re-Injection Centrifugal Compressor During Full-Load, Full-Pressure . Symptoms of an AC compressor shaft seal leak can include a distinct odor coming from the vents, decreased cooling performance, and the air conditioning. . To further confirm a shaft seal leak, a pressure test can be conducted using specialized equipment. This test involves pressurizing the AC system and monitoring the pressure readings to .1259, Page 1 International Compressor Engineering Conference at Purdue, July 16-19, 2012 Spool Seal Design and Testing for the Spool Compressor Greg Kemp1*, Joe Orosz1, Craig R. Bradshaw2, Eckhard A. Groll2 1 Torad Engineering LLC, Alpharetta, GA 30004 2 Ray W. Herrick Laboratories, Purdue University, West Lafayette, IN 47907 * Corresponding Author To meet a huge demand for both new and repair of Dry Gas Compressor Seals, AESSEAL ® is pleased to announce a further £500,000 investment in their testing facility. In addition to doubling the current capacity, this investment increases the diameter of Dry Gas Compressor Seals that AESSEAL ® can manufacture, refurbish and dynamically test up to .

DGS) into one of the most reliable and maintenance-free sealing solutions availa- . tomers are welcome to witness all seal test-ing and inspection. Leakage rates 350 ft/s 8 7 6 5 4 3 2 1 0 226 198 170 142 113 85 57 28 0 0 500 1 000 1 500 2 000 2 500 [psi] A test apparatus is introduced to isolate and measure the spool seal's performance independent of the compressor. It is concluded that the hybrid design is highly effective and well suited for .

nitrogen gas seal performance

Resultado da 12. 128,910 gostosa dando de 4 FREE videos found on XVIDEOS for this search.

compressor seal testing|nitrogen gas seal performance